Hot sale professional candle wax and fragrance machine auto mixing and filling system for scented candle making

- Overview

- Parameter

- Inquiry

- Recommended Products

|

Name

|

Candle Filling and Melting Machine for Fragrance Separately

|

|

Power

|

6KW

|

|

Voltage

|

220V 50Hz single phase

|

|

Functions

|

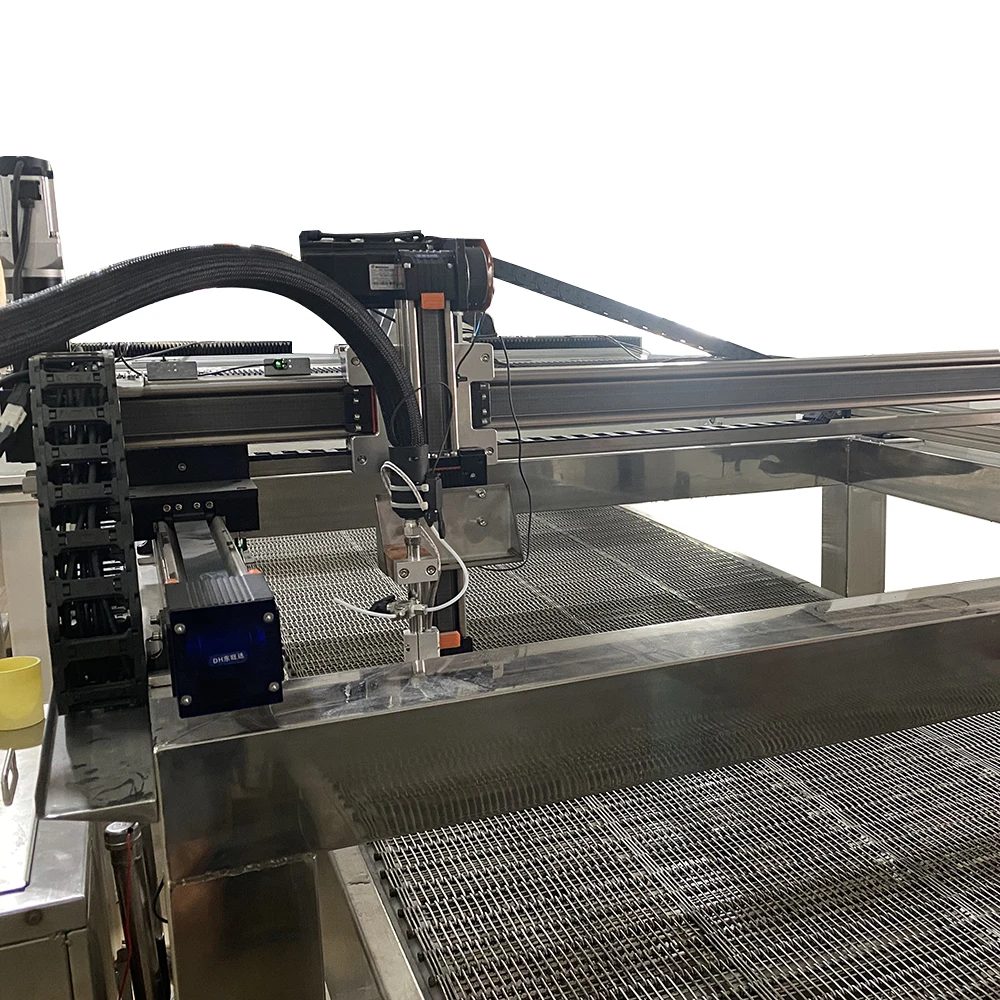

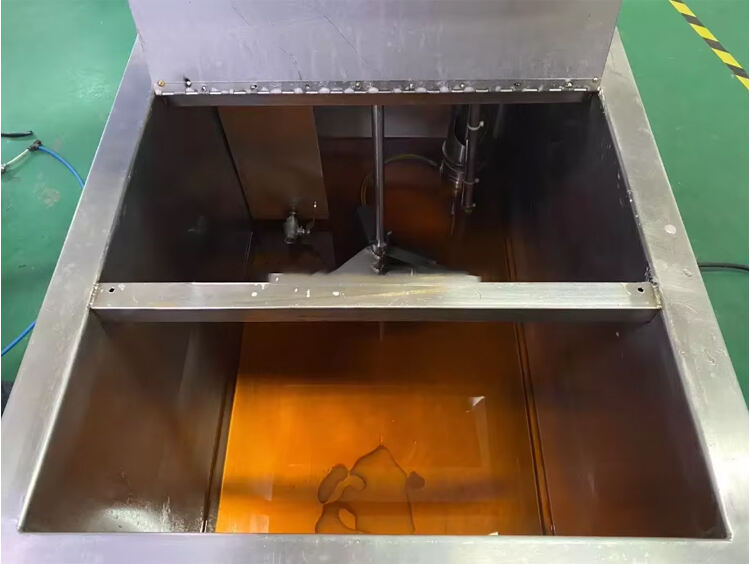

melting ,mixing and filling wax and fragrance separately by different pump

|

|

Speed

|

normally melted within 2h

|

* Material :Double Layer #304 Stainless Steel

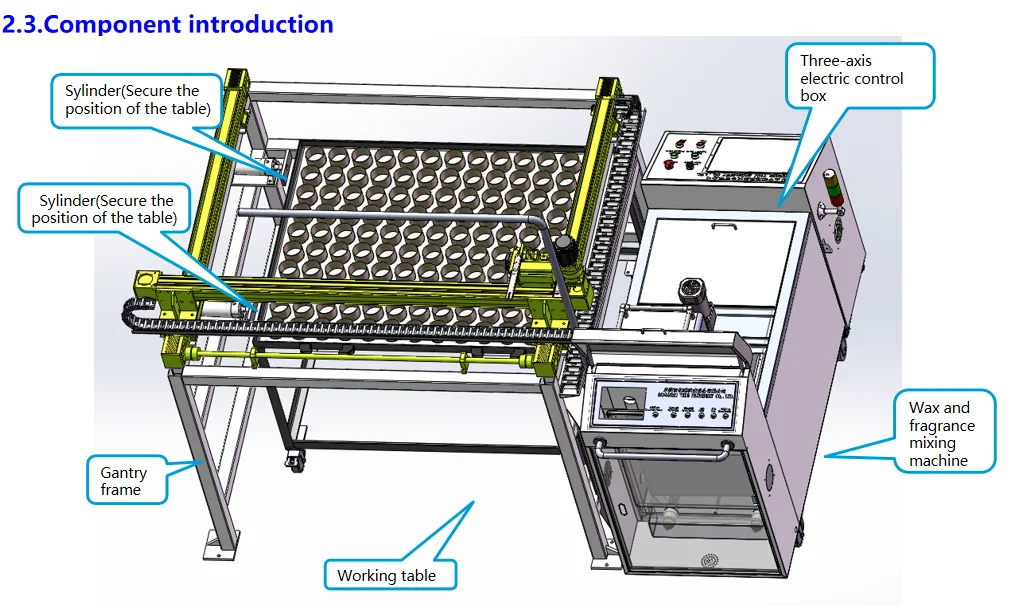

* Intelligent induction filling, no cup no filling, automatic positioning filling.

Solve the problems of high labor cost, easy fatigue of workers and small space of workshop in candle factory, and efficiently produce aroma candles.

* Lightweight designs that are fully insulated and cool to the touch

* Wand dispensers that let you pour in precise, controlled ways

* Options to work with paraffin, soy, vegetable, palm, beeswax, coconut wax, cosmetics and more

* Machines that are easy to transport when necessary

* 160lbs to 560lbs capacity

We are based in Guangdong, China, start from 2014,sell to Domestic Market,North America,South America,Mid East There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Wax Melter Tank,Wax Filling Machine,Wick Inserting Machine,Wick Cutting Machine,Tealight Packing Machine

4. why should you buy from us not from other suppliers?

We major in produce filling machine,capping machine,labeling machine,sealing machine,coding machine and packing machinery with high quality and best price. We willing to offer our best service for every customer from different countries.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T;

Language Spoken:English

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB