Name |

Stainless Steel Pump Hot Wax Scented Candle Filling Machine |

Power |

10KW |

Voltage |

380V/220V Three phase |

Customize |

Yes |

Wax Filling Machine

*This is hot material filling machine, especially for wax

suitable for beewax ,soy wax,parrafin wax,jelly wax, hair removal wax, furniture wax etc.

The pump has function of heating which can prevent from blocking of the pump

* Filling for aluminium cup,glass cup,plastic cup, bottles all ok

* Filling volume can be adjustable from 1ml-5000ml. It is PLC controlled, filling by setting up the filling volume and intervals.

What it can help with our candle making:

1. clean, no need extra cup cleaning

2. accurate, equal volume for each cup, help brand building

3. no blocking, with pump heating and reversing, no headaches with wax blocking anymore

4. save labor cost, with machine productivity can be double while half labor cost

Automatical Filling

1. After setting up the filling volume and intervals on the touch screen you can handle the filling nozzle to fill one by one, very easy to operate, no extra work is needed.

2. At same time, the pump has the function of heating and reversing which can keep the pump and tubing empty after working and no bother of stock for the next time working.

3. The pump has been upgraded to stainless steel type which means this machine can help you filling even if your scents are very corrosive.

Our team are specialized in CANDLE MAKING MACHINES, any requirement or feedback are welcome!

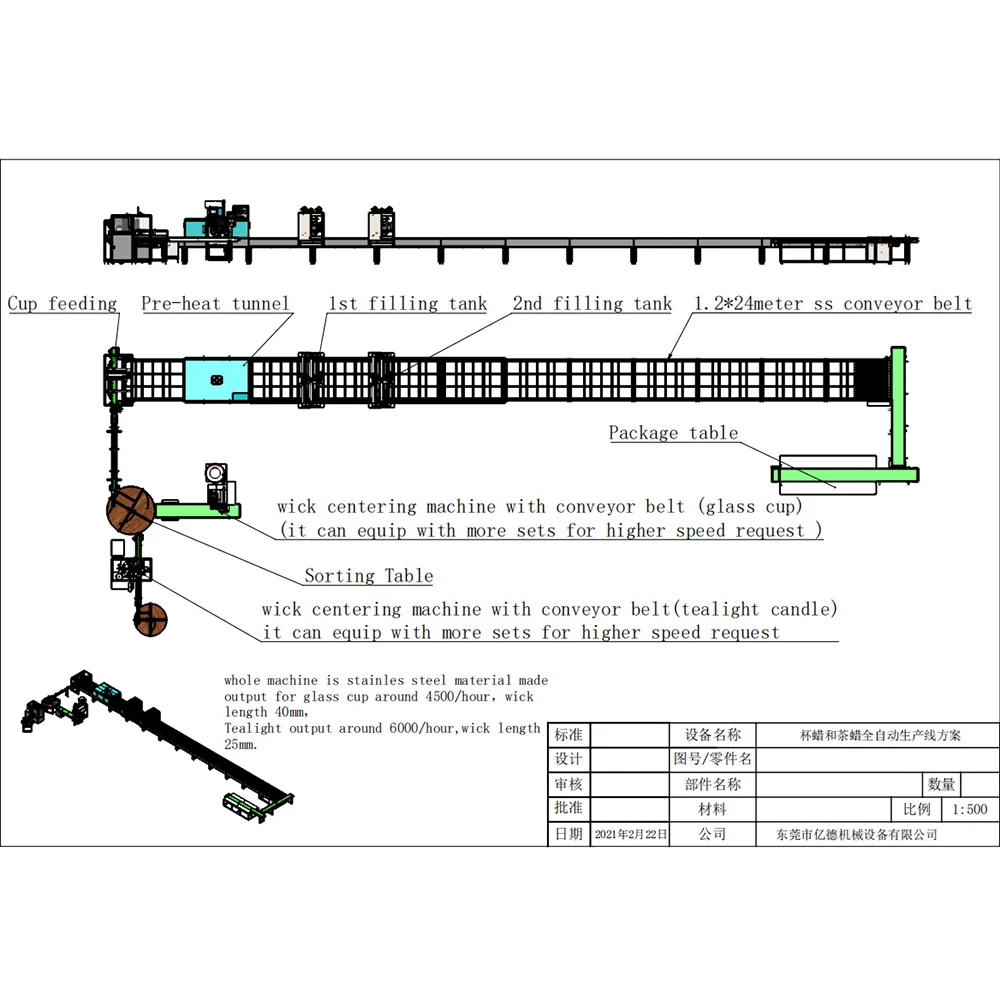

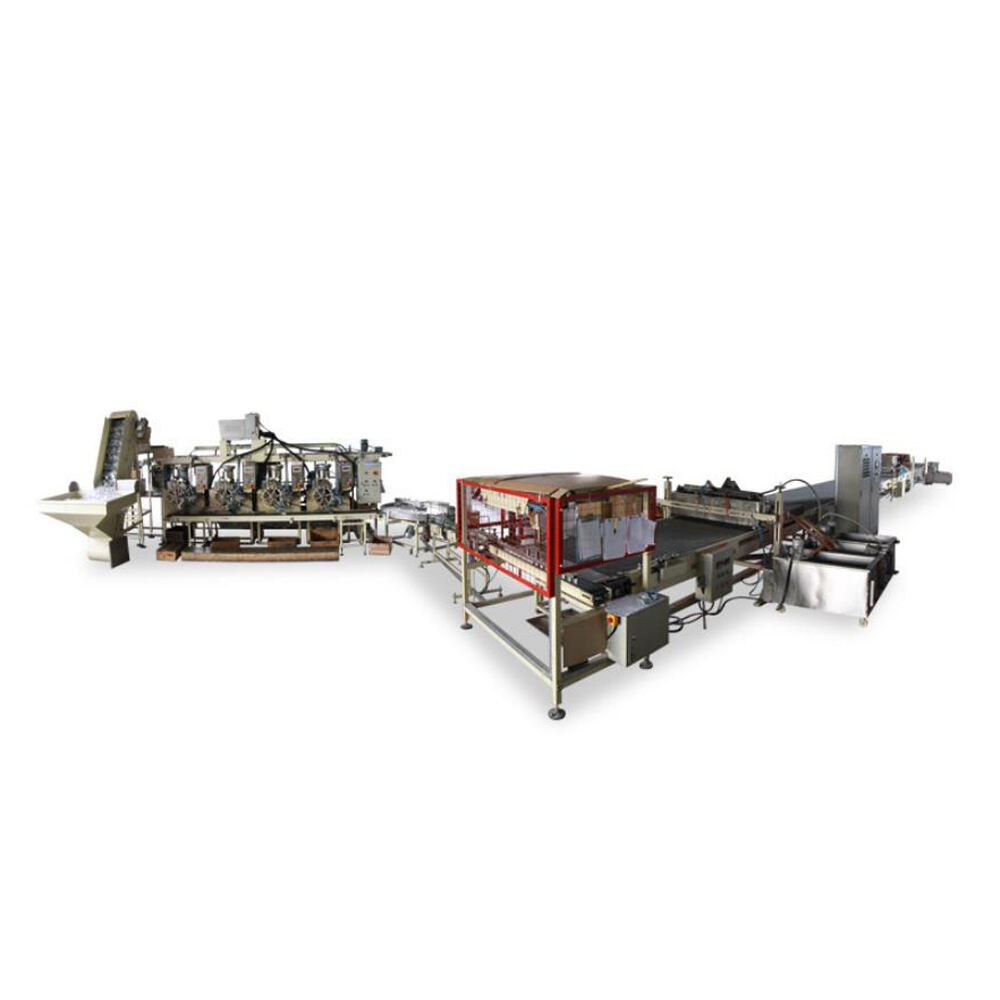

The China Custom Floor Wax Filling Machine Cosmetic Wax Candle Production Line Heating Warming and Pouring System Automatic by Yide is a state-of-the-art solution for creating top-quality wax products and services on a commercial scale. This was created to minimize waste, improve effectiveness, and enhance overall quality to meet with the growing needs for the cosmetic wax and candle industry.

This was made up of several elements, including a custom floor wax filling machine, warming and system, and a pouring automated system. These components work seamlessly together to create a highly manufacturing that is both efficient and dependable. The customized floor filling device was created to fill wax containers of various sizes and shapes with precision.

The warming system was created to make sure that the wax is melted to the right pouring consistency. The machine is fully automated, which means that it could be easily managed to look after the right temperature to avoid underheating or overheating of the wax.

The automatic pouring was created to control the movement of wax during the filling process. This helps to ensure that no wax is spilled or squandered, and that the wax is evenly distributed in to the containers. The system is fast and accurate, permitting you to create large volumes of wax products and services in a short time.

The Yide’s China Custom Floor Wax Filling Machine Cosmetic Wax Candle Production Line Heating Warming and Pouring System Automatic is suitable for a wide assortment of products and services, including cosmetics, candles, and also other wax-based products and services. The equipment is easy to run and continue maintaining, and it possesses an advanced level system that monitors and manages the whole manufacturing procedure. This makes it an exceptional choice for organizations that are looking to increase their production capability and improve their overall production of top-notch wax products.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB