Introduction to the wick gluing process for candle production

The wick gluing process in candle production is an important step in ensuring that candles burn properly and last long. The wick gluing process involves fixing the wick to the base or center of the candle to ensure stable support and flame when burning.

Choosing the right wick: Choose the right wick for the type and size of your candle. The thickness and material of the wick will affect the effectiveness and longevity of the burn.

Pre-treating the wick: The wick is usually soaked in candle wax solution first, which helps to strengthen the wick and prevent burn off. Sometimes the wick is also treated, such as by applying special chemicals, to enhance the burning effect.

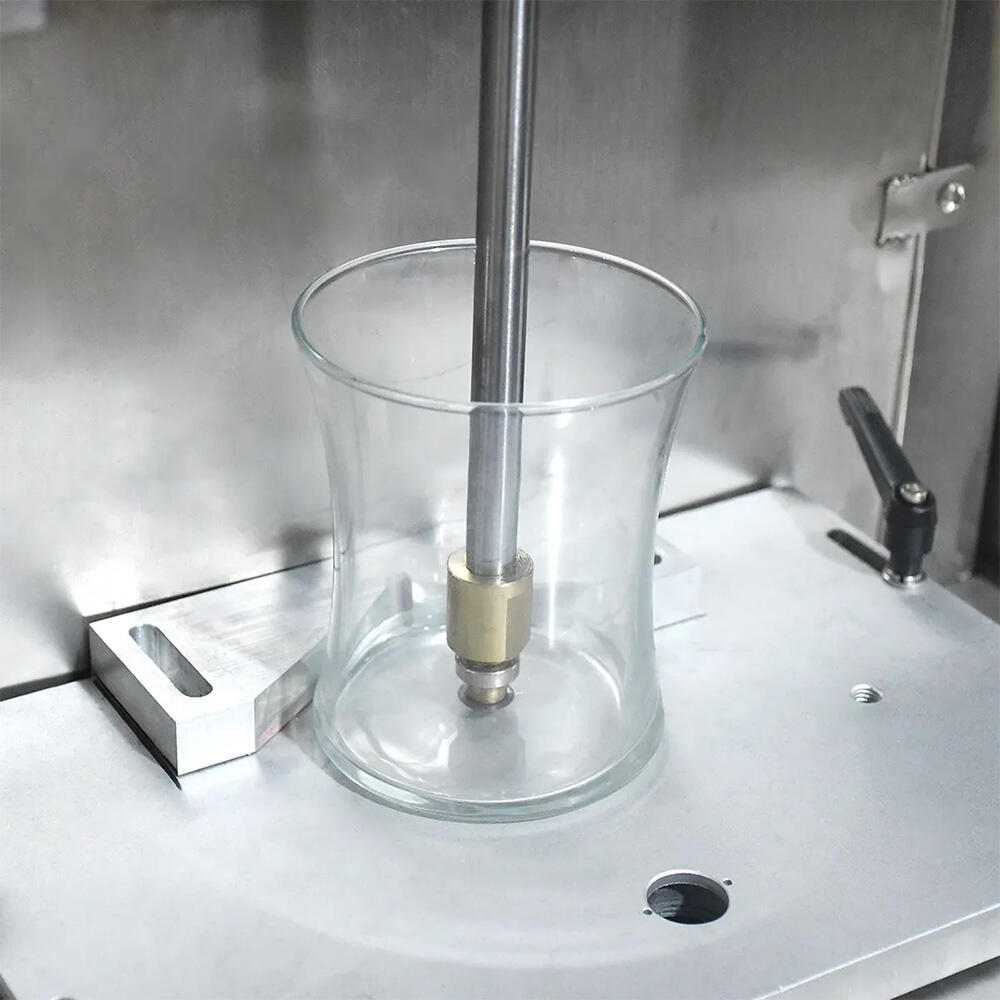

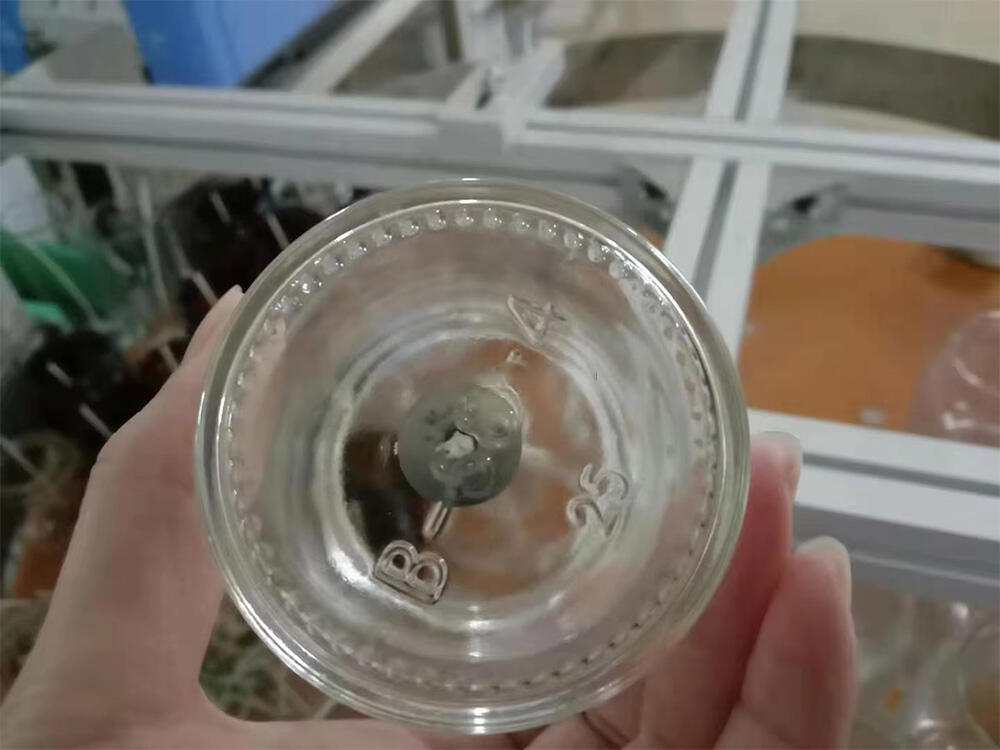

Securing the wick: The wick is secured to the bottom or center of the candle. This is usually done in a candle mold to ensure that the wick stays in the correct position when pouring the wax.

Adjusting the height of the wick: Make sure the height of the wick is appropriate for the size and type of candle. If the wick is too long or too short, it will affect the burn.

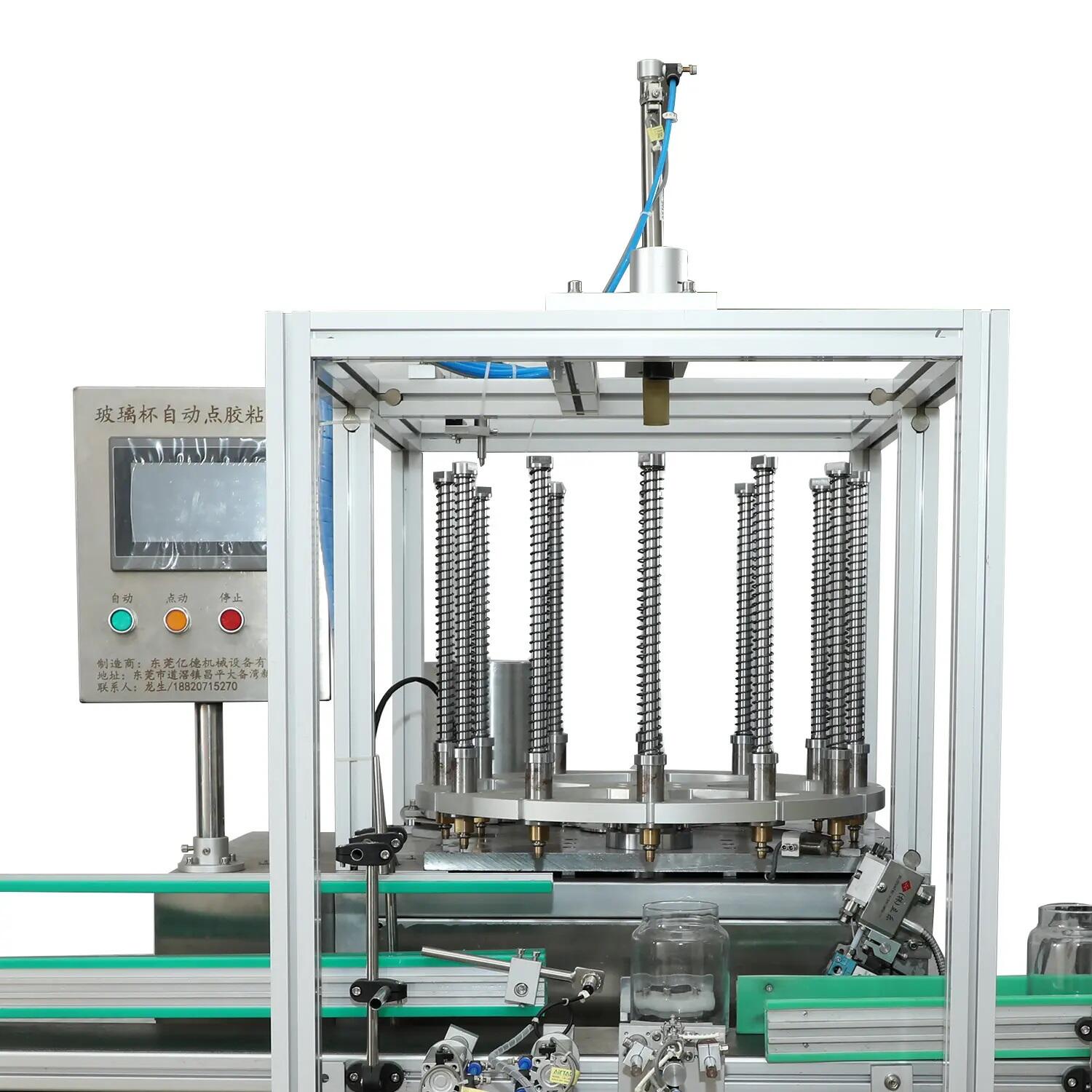

Stabilizing the wick: Some manufacturers use special tools or techniques, such as wick jigs, to ensure that the wick remains stable during the candle manufacturing process.

Final Trimming and Adjustments: After the candle has been manufactured, final trimming of the wick may be required to ensure that it is the proper length and position.

Through the wick gluing process, candle manufacturers are able to ensure that each candle will burn steadily and last as long as desired and for as long as desired.

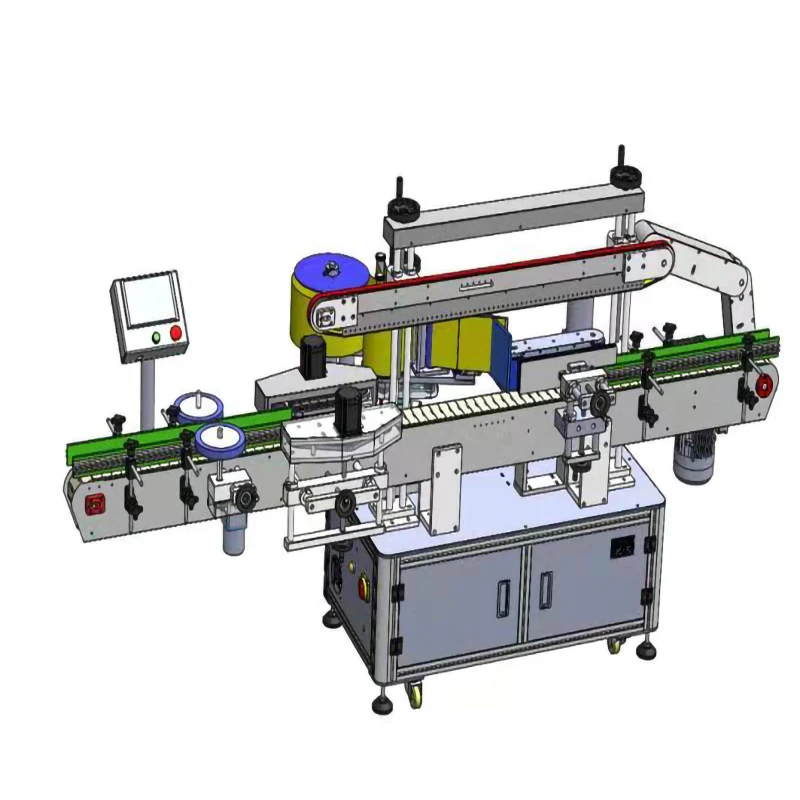

Recommended Products

Hot News

-

How to choose wax melting equipment for candle factories

2024-07-26

-

Introduction to the wick gluing process for candle production

2024-07-12

-

Candle making machines can be divided into several categories?

2024-06-25

-

Candle making and how to use a candle machine

2024-06-13

-

The Benefits of Wax Candle Machines in Mass Production

2024-05-29

-

How to use the candle machine correctly?

2023-12-19

-

Foshan Candle Factory Livestream Successfully Completed – Replay Available Now!

2025-05-13

-

Revolutionizing Candle Manufacturing: Automated Tealight & Scented Candle Production Line

2024-10-18

-

Brief introduction to fully automatic machines, feel free to contact us to know more details.

2024-09-26

-

Customer Success Story!

2024-09-14

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB