Ana Özet - Otomatik Mum Yapma Makineleri Hakkında Başlangıç Seviyesinde Bir Rehber

Mum yapımı, birçok yıldır var olan bir sanattır, ancak otomatik mum yapma makineleri modern teknoloji kullanarak mumların nasıl yapıldığı konusunda oldukça büyük bir değişim sağladı. Bu devrimci makineler, keskin teknoloji, doğruluk, hız ve yüksek verimlilik ile mum ekipmanı üretim işletmelerini yeniliyor ve aynı kaliteyi korurken üretimi artırıyor. Bu rehberde otomatik mum yapma makinelerinin dünyasını açığa çıkaracak, tüm yeni özelliklerini inceleyeceğiz ve neden hızlı çözümlerde başarıyla yer aldıklarını anlatacağız. Ayrıca bunları neden dikkate almalısınız konusunda bilgilendireceğiz.

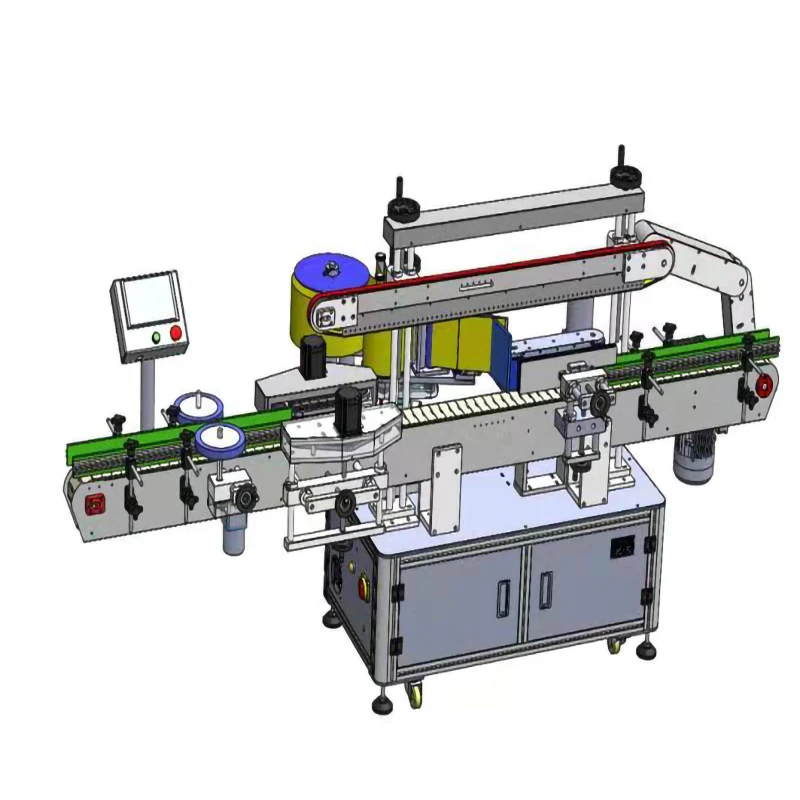

En Yeni Verimli Otomatik Mum Yapma Makineleri

Mühendislik imalatının en ideal örneği, bu nesilden tek türü olan yeni tamamen otomatik mum yapım makinesidir. Bitmiş ürünlerin paketlenme veya kutulanma işlemini takip etmeden önce eriyen mumdan dökümü, ipliği ve hatta mumların atışmadan önce soğutmayı kapsayan her bir mum yapımı aşaması bu makinelerle programda sorunsuzca entegre edilebilir. Bu makineler, mum viskozitesini korumak için sıcaklık kontrol sistemleri, iplik konumunu hassas bir şekilde ayarlamak için otomatik iplik yerleştirme mekanizmaları ve gerektiğinde lezzet eklemek için renk enjeksiyonu gibi özelliklerle donatılmıştır. Sezgisel kontroller ve ayarlanabilir özellikler, farklı mum şekilleri ve boyutları arasında hızlı geçiş yapmayı kolaylaştırır ve esnekliği artırırken duruş süresini azaltır.

Yüksek Hızlı Mum Üretiminde Gizemlerin Açıklanması

Otomatik mum yapım makinesi sayesinde, yüksek hızda mum üretimini hayal ettiğimiz o günler geride kaldı ve şimdi herkes bunu gerçekleştirebilir. Bütün bu gelişmeler, akıcı iş akışlarına ve çoklu görev yeteneğine bağlıdır. Bu süreçler geleneksel yöntemlerde olduğu gibi sırayla ve adım adım yapılmasına gerek yoktur; bunları aynı anda yapmak üretim süresini büyük ölçüde azaltır. Saatte onlarca veya yüzlerce (hatta bazı modellere bağlı olarak binlerce) mum üreten bu makineler her zaman en üst düzey kalite standartlarını sağlar. Bu kadar hızlı bir çıktı, sadece büyük siparişlere iyi hizmet eder değil, aynı zamanda işletmelere pazar hareketlerine ve mevsimsel değişikliklere son derece hızlı bir şekilde tepki verme şansı tanır.

Satılık Devrimci Mum Ekipmanlarıyla Başarı Dünyasına Giriş

İşletmeleri en yeni yüksek teknoloji otomatik mum yapım makineleriyle donatmak, onların karlılığıyı artırmasına yol açar. Tabii ki, eğer üretim hattı otomatize edilirse, bunun yanı sıra izlemek için gereken insan sayısı da büyük olasılıkla çok daha az olacaktır ki bu da işgücü maliyetlerini azaltmaya yardımcı olabilir. Makine ile yapılan mumların hassasiyeti ve tutarlılığı, malzeme kaybını daha da azaltır; bu da her damla kandırağının satılabilir bir ürün üretebildiği anlamına gelir. İşgücü ve malzeme maliyetlerini azaltarak her birim başına daha düşük üretim maliyeti elde edersiniz, böylece daha yüksek kar oranlarına sahip olursunuz. Bu makinelerin sunduğu gibi daha fazla iş yapabilme yeteneğiniz olduğunda, daha yüksek kalitede veya daha tutarlı bir şekilde ve daha az para (daha az insan saati) harcayarak - işiniz şimdi daha iyi marjlarla daha büyük sözleşmelere yer açabilir.

Otomatik Maquinaria Aracılığıyla Etkinliğin Zirvesine Ulaşma

Otomasyon, herhangi bir kârlı üretim işleminin temel taşıdır ve otomatik mum yapımı makineleri bu kavramın parlak bir örneğidir. Bu sistem, akıllı sensörler ve kontrol sistemleri kullanır ve bu sistemler üretim sürecini gerçek zamanlı olarak izleyebilir, böylece herhangi bir sapma veya anormallik tespit edilir ve nihai ürün üzerinde etki yaratmadan önce düzeltilir. Sistem, makinaların verimliliğinizi bozan bir sorunla karşı karşıya kalmamasını sağlamak için bakım uyarıları sağlar. Ve üretim ayarlarını programlama ve depolama, tekrarlanabilir sonuçlar sunarak favori mum tasarılarınızı en az kurulum zamanıyla kolayca yeniden oluşturmanıza olanak tanır. Bu geliştirilmiş verimlilik, üretimi hızlandırır ve hatta en seçici müşterilerinizin taleplerini karşılamak için sıkı kalite kontrol gereksinimlerini karşılar.

Top Candles Machines: Makinelerle Gelecek Oluşturuyor

En İyi Düzeyde Mum Yapımı Makineleri ve Değişen Endüstri Zamanları: Her işletmenin hızlı değişen endüstriye uyum sağlamak için en üst düzey makinelerde yatırım yapması kritik importance. Kişiselleştirilmiş mumların popülaritesinin artmaya devam ettiği ve tüketicinin alışkanlıklarının değiştikçe, ekipmanların esnek ve güncellenmiş teknolojiyle donatılmış olması çok önemlidir. Modülerlik aklında tasarlanan bu makineler, yeni teknolojiler ortaya çıktığında yükseltilebilir ve uyarlanabilir durumdadır. Sadece anlık üretim gereksinimleri için değil, aynı zamanda yenilik ve yeni pazarlara girme olasılığı için araçlar olarak iş görürler. Otomasyonu bugün benimseyen işletmeler, rekabetçi avantajlarını korurken rakiplerden daha hızlı yeni eğilimlere uyum sağlayabilir ve takipçiler yerine öncü olurlar.

Nihayetinde, Otomatik Mum Yapımı Makinelerinin Önemi

Sadece başka bir makine değil, bu otomatik mum yapımı makinesi, Mum İşletmesi alanında yeni bir üretkenlik ve kârlılık dalgasına giriş kapısıdır. Otomasyonun ötesinde, büyümeye bir adım daha ileriler ve işletmeleri yeni seviyelere çıkarır. İşlemleri genişleştirmek isteyenlerden birisinizse, çıkışı artırmak ve dinamik bir pazarda hakim olmak istiyorsanız, otomatik bir mum yapımı makinesine yatırım yapabilirsiniz.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB