A Semi-Automatic Candle Making Machine- Handy for Candles Makers

Is this because you are tired of the stringent method used in candle manufacturing? Although candle making looks like a very traditional pursuit lately, it is still an expanding field posing exceptional evolutions within the creation of candles. Integrating a semi-automatic candle making machine in your process makes all the difference when it comes to increasing production, saving costs and maintaining quality throughout your candles.

Buying a semi-automatic candle making machine is an investment that not only helps small scale business operations, but also scales up the production of candles. Time and energy are saved by using these machines, rendering them able to make a lot more candles quickly than traditional manual methods. The machines make use of accurate measurements and automated procedures required in order to deliver consistent high standard candle products. Besides, they save time and labor costs by automating processes that would otherwise need human intervention.

The development of the semi-automatic candle making machine marks a major advancement in the technology scene at Large Candle Company. These machines have streamlined the candle-making process, making production faster and easier than ever before. Using automation, the wax pour is controlled so each candle maintains quality and consistency with every batch.

If you are using a semi-automatic Candle Making Machinery is that, YOU ENSURE SAFETY FOR THE MACHINE OPERATOR BECAUSE IT NEEDS TO LOOK PERFECT IN FRONT OF HANDLER SO THEY MAY JOINT OTHER PART. Many safety features are installed in the machine to make it safe for people and avoid as much danger during use. For example, a safety switch cuts off the machine while its cover is opened so that no doer can get harmed. The machine is also designed to not overheat, hence prevents combustion and hot wax accidents.

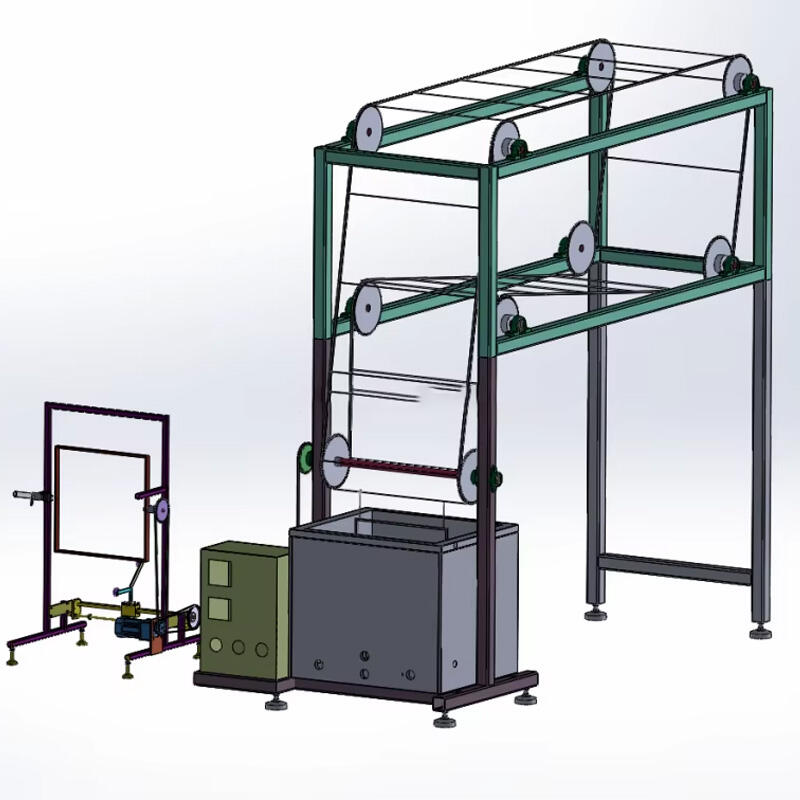

A semi-automatic candle-making machine is easy to use, even for novices in the world of candle making. The wax is first melted contained in the gadget before other flavoring and coloring are an introduced. A wick is then inserted into the mold, and molten wax is poured in through a hole on top of the machine to fill it in such a way as outlined by our specification list for what we refer internally as 'lavender gear'. Once this happens, liquid nitrogen freezes everything solid around again; shaping that now cold mixture' rounder shape next step comes when all heat specific process burns out excess gas inside pipes connected with those devices used either burner flames causing evaporation. Lastly, taki out candle from the mould is just something you do without any effort.

Customer Support: A customer support executive will discuss the complaints, issues and other relevant things about quality on phone.

Candles made with semi auto candle making machine are high in premium quality, consistent. These machinery have been constructed to stand the test of time, providing a trusted resources for business candle makers. In the case of technology malfunctions, immediate support from the manufacturer's customer service staff is available to fix it as soon a possible so that there are no halts in terms of operations for the user.

Three QC employees semi automatic candle making machine steps quality control safety testing assure machine meets standards safety uses.With professional RD team comprising 5 members offer customized solution 48 hours. ideal equipment candle-making business. We able build machine according requirements.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images sent clients prior shipment. After-sales problems resolved within hour solution provided within 24 hours. We have professional foreign trade team helpful service usually highly semi automatic candle making machine clients. And we have highly skilled RD team who make your ideas become real machine. Production responsible every step production until receive product.

equipment made semi automatic candle making machine steel made food use corrosion-resistant as well anti-rust. It also resistant high temperatures.standard motor replaced with stepper motor servo motor improve accuracy efficiency. pump constructed stainless steel food grade type instead metal plastic.We have variety sizes pump, such 4L,6L,10L 20L suit different requirements filling ranges. touch screen PLC makes simple set parameters such filling frequency, filling speed as well temperature requests more. There a full range candle equipment available, not the semi-automatic kind also fully automated type. entire range machines been updated make more flexible durable.

Dongguan Yide semi automatic candle making machine Co.,Ltd specializes production candle machines. most popular products wax melting tank, wax-filling machine, wicking machines. We more 100 semi automatic candle machine stock, two fully automated lines available.