Wick Types Candle Making Machine : A Different way To Make Pillar Candles

Would you like to make homemade candles but thought it was too hard, too expensive or took a lot of time Well, look no further! Enter, the wick candle making machine. So let's check out the magic they make with this wonderful new invention in candle making!

Benefits of using Wick candle making machine

A wick candle making machine also allows you to reap a ton of benefits while eliminating all that hassle:semicolon

User Friendly: The machine is designed for ease of use with very obvious and easy to understand instructions.

Saves Time and Money: No more trips to the candle store for you! If you have this machine, then you can create multiple candles without spending much money. And it is much faster than creating candles the conventional way.

Candles that are Beautiful: With the wick candle making machine, every piece of merchandise is guaranteed to be distinctive and unique.

Diversified Use: You can use these wax melting machines to create candles for personal use, as gifts-like birthdayXmas presents or could just re-sell them using one of the creative ideas you may have found in different sources.

The candle making world too has seen a revolution thanks to super-sophisticated machines like the wick candle making machine. This technology that is head and shoulders above the rest not only allows making candles an easier process, it turns a potentially dangerous task into something fun for people of all ages.

Your safety is the most important when using any kind of a machine and it stands true for wick candle making machines. Following are some of the safety essentials that makes this machine a trustworthy option:

Thermo Safety Switch - automatically turns off the machine in case of high temperatures to protect against heat.

Cut-off Switch- It assures against useful issues, for example, overloading by ending the machine when it is required.

Emergency Stop Switch- This will be used to stop the machine with immediate effect from working in any unforeseen emergencies.

Fireproof materials: The machine is made to use the heat so even if something gets caught on fire, it does not burn completely.

Want to learn how this amazing machine works? Carry out these small steps to make your candles even better and you are done.

Clip the melting pot back into place and then slide it on onto power machine

Rotate the wax until it completely melts then pour them slowly in the shape.

Thread the wick through and then leave to set.

After setting the candle, extract it from its mold and cut down to size your wick;

Some are all in one while others need to be decorated and even scented or you can add your own embellishments.

The investment in wick candle making machine is the same as an investment made for long lasting and durable. Its longevity and appropriate maintenance might make it your company for the next few years on your candle making trip. Though, should you ever need any help or troubleshooting the manufacturer is only a message away.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images sent clients prior shipment. After-sales problems resolved within hour solution provided within 24 hours. We have professional foreign trade team helpful service usually highly wick candle making machine clients. And we have highly skilled RD team who make your ideas become real machine. Production responsible every step production until receive product.

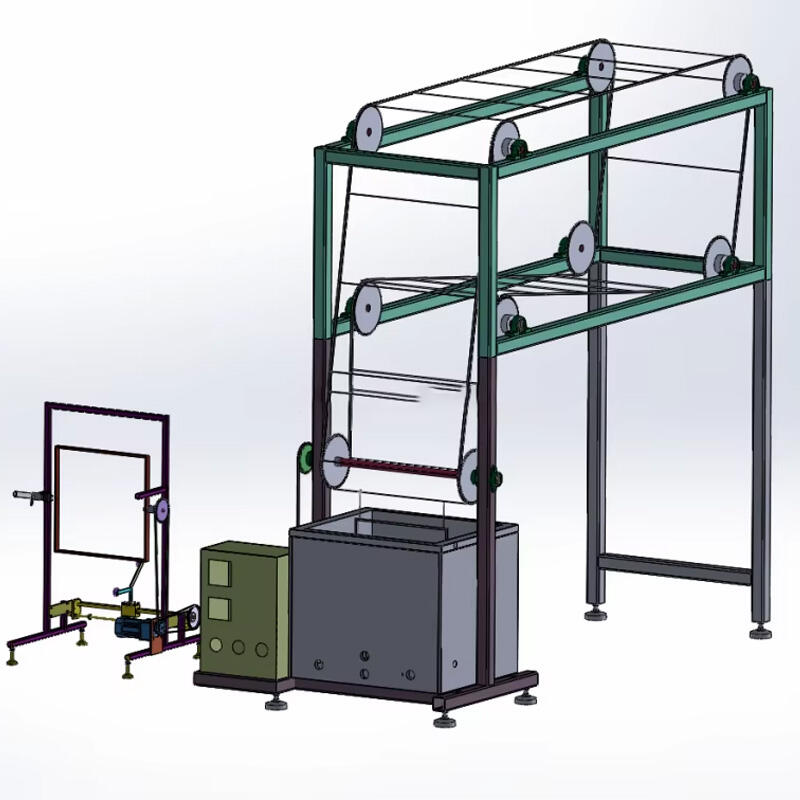

Dongguan Yide Machinery Co.,wick candle making machine specialising manufacture candle machine, main product wax melting tank, wax filling machine wick machine. factory cover area 2500 square meters. standard semi-automatic candle machines stock over 100 sets. fully automated line always two sets stock. believe providing most innovative engineering solutions candle manufacturers across world.

wick candle making machine equipment constructed food grade stainless steel 304,anti corrosion,antirust resistant high temperatures.standard motor replaced servo stepper motor order increase precision efficiency. pump made stainless steel food grade 316, not steel plastic.have different sizes pumps, such 4L, 6L, 10L 20L meet different filling range. PLC touch screen makes easy set parameters, such filling frequency, filling speed as well temperature requests more. There's broad selection candle equipment available not just semi-automatic, as well fully-automatic one. machines all updated details, be more flexible more stability.

Three QC employees Eight stages wick candle making machine control, safety tests ensure machine compliance requirements safety usage.We a team comprising five professionals provide with custom solution 48 hours. perfect machine your candle making business. can make machine according your specifications, just meet requirements.