Are you a fan of candles? Ever wondered about making your own candles. If your answer is yes then a wick candle machine could be the best thing for you. A wick candle is a machine made for simplifying the process of making candles and it will finish your work faster than traditional handcraft works. In this extensive post, we are going to look at the different advantages of a wick candle machine as well as its various recent improvements and safety measures that one should have when operating it.

Advantages of Wick Candle Machine For one, it speeds up the candle-making process in comparison to hand crafting them individually resulting in a higher volume of candles created over time. Also, the accuracy of a wick candle machine makes it impossible to create other candles with difficult aesthetics before you can test and adjust them again. Finally, the value of using this machine for long-term purposes is cost-efficient as one can produce candles much faster ensuring there are more numbers to be sold off which will generate a profit in return.

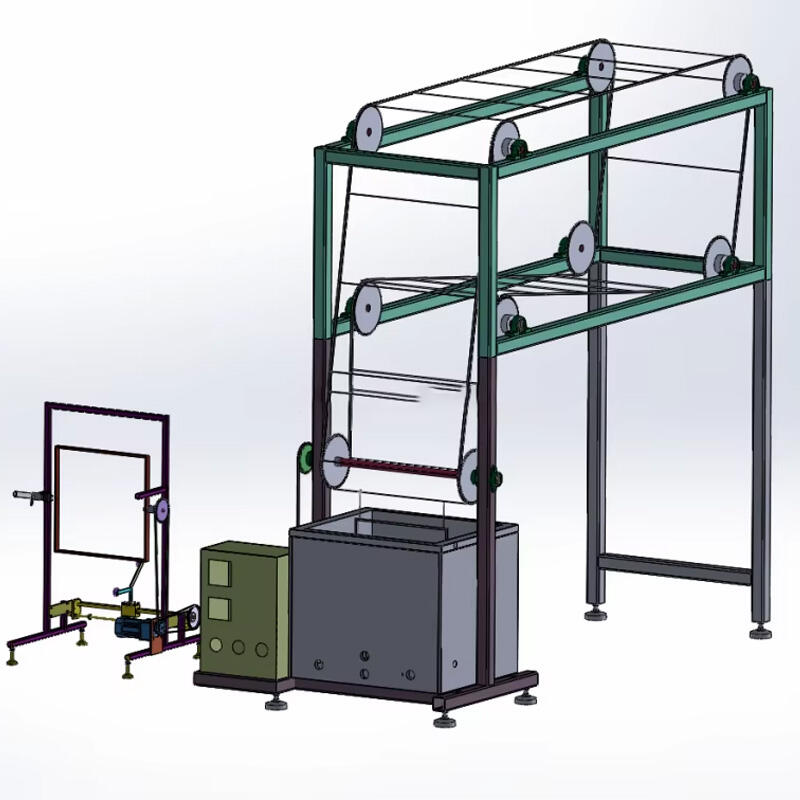

While wick candle machines have been around for a long time due to recent technological advancements, they advanced in their functionality and potential. Today, modern wick candle making machines are more versatile and can make traditional candles as well to floating or twisted design candles. Naturally, because of this new exciting development you can now pick the exact style of candle that you would like and then be able to perfectly make it.

The safety requirements when using a wick candle machine are fundamental, the devices that manufacture candles contain many functions to make these working systems very safe for users. The machine features a protective cover that keeps hands out of the hot wax, and safety measures to prevent spillage or reduction in burns. Safety is paramount, allowing users to use the machine in full faith that they will be taken care of and ready for their loved ones.

Follow the step by step guide on how a wick candle machine operates

A wick candle machine is easy to use and works on basic steps. The first step involves switching on the machine and connecting it to a power outlet so that you can set up the temperature. The wax you have chosen is then poured into the machine, a common choice for this would be beeswax. Wrap the cotton string around, while placing it in and making sure this is centred correctly with a taut top line of rope After these steps, the machine can be now activated and it will make candles with minimal effort.

Also note that you should contact the manufacturer with any problems regarding your wick candle machine. So, in such a case, they can guide through the troubleshooting process or help you with your queries related to machine and also provide repair/replacement facilities if needed. This level of dedicated support is what allows users to continue having confidence in the performance of their machine and reassure them that any future problems will be identified and solved quickly.

Three QC employees wick candle machine steps quality control safety testing assure machine meets standards safety uses.With professional RD team comprising 5 members offer customized solution 48 hours. ideal equipment candle-making business. We able build machine according requirements.

wick candle machine Yide Machinery Co.,Ltd focused production candle machines. main product wax melting machine, filling machine, wick machine. manufacturing plant covers 2500 square meters. standard semi-automatic candle machine 100 sets, fully automatic line always keep two sets stock. believe sharing most efficient engineering solutions candle manufacturers around world.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images sent clients prior shipment. After-sales problems resolved within hour solution provided within 24 hours. We have professional foreign trade team helpful service usually highly wick candle machine clients. And we have highly skilled RD team who make your ideas become real machine. Production responsible every step production until receive product.

equipment made food grade stainless steel 304, anti corrosion, antirust resistant high temperatures.order ensure precision effectiveness, stepper motor servo motor replaced normal motors. pump constructed stainless steel food grade type 316, metal plastic.There variety sizes pumps, 4L/6L/10L 20L accommodate different filling capacities. PLC touch screen desgin easy set parameters, such filling rate, filling distance temperatures, filling speed more. full range candle-related equipment selected, just wick candle machine automatic type, also fully automated types. machines been upgraded make more flexible durable.