When your answer is "yes", here i'm imparting the great manual candle gadget you ever have visible.

Candles have been around for hundreds of years to light up the world, create warmth in a room and assist with religious needs. The creation of manual candle machine revolutionized the labour industry for candles, it allows people these days to make their own candles with different size and shape. In this article we will be talking about its process, characteristics advantages, safety precautions for manufacturers along with creative point of view and few step by step guidelines on how to use a manual candle machine in brief followed up with quality standards as well.

The manual candle machine has many benefits, so it is the first choice for people who love candles. It is not only user-friendly and does away with the complexity of machinery or electricity, also making it cost-effective but at the same time highly efficient as well. This ease-of-use is a direct result of them being straightforward to operate without the need for sophisticated training. Manual candle machines also provide a higher degree of customization as users can make candles in different shapes, size and colors based on their need. Additionally, these machines not release harmful gases or other chemicals affecting the air as well. Lastly, the concise cost of producing candles using a manual candle machine would not be much, which is profitable for upcoming entrepreneurs.

The hand candle machine can be considered a real innovation that has changed the world of candles. Created to make the candle making process as easy and cheap enough for you also. This value proposition: the need for candle making, manual candles machine to be much faster, orders of magnitude cheaper, and provide a robust enough design that can make owners last generations is astounding when you consider its revolutionary nature in an industry long dominated by expensive equipment and skilled labor.

The Manual Candle Making Machine is designed above all to guarantee the safety of its users. Crated with rugged, top-grade materials the machine is designed to keep away accidents/injuries from use. Safety features of the wax machine is protects users from coming into contact with hot wax, emergency stop button stops your unit incase not planned for issue.

Ease of Use

The manual candle machine is easy to handle that everyone can have an interest and practice in making candles. Firstly you need to put your wax in the container, turn it on and let it do its thing. The wick is submerged in the melted wax as it burns. From there, users can make the candle with a variety of molds and customize color/fragrance themselves. The machine is capable of producing everything from pillar and votive candles to scented options.

How to Use (Step-By- Step Detailed Guide)

How To Use Manual Candle Machine [Step By Step]

Prepare the Wax Container

Make sure bowl is clean and dry.

Put the wax in the jar.

Power on the machine and get your wax melting.

Insert the Wick

See how the wick is moving automatically into hot wax;

Make sure the wick is in place down the middle of your mold.

Shape Your Candle

Candlemaking: Use molds to form your candle with ease

This kind of soap has the last touch with color and fragrance, doing so in a nice way aesthetically speaking.

Allow the Candle to Harden

Allow the candle to cool and solidify.

When the candle is set, withdraw it from the mold.

The manual candle machine is low maintenance, but maintaining a clean and dry operation can prevent rust and corrosion. Do not keep the machine under direct sunlight, store it away from a warm place. If there are any problems, the user manual is very clear and if you do have technical problems then support from the manufacturer.

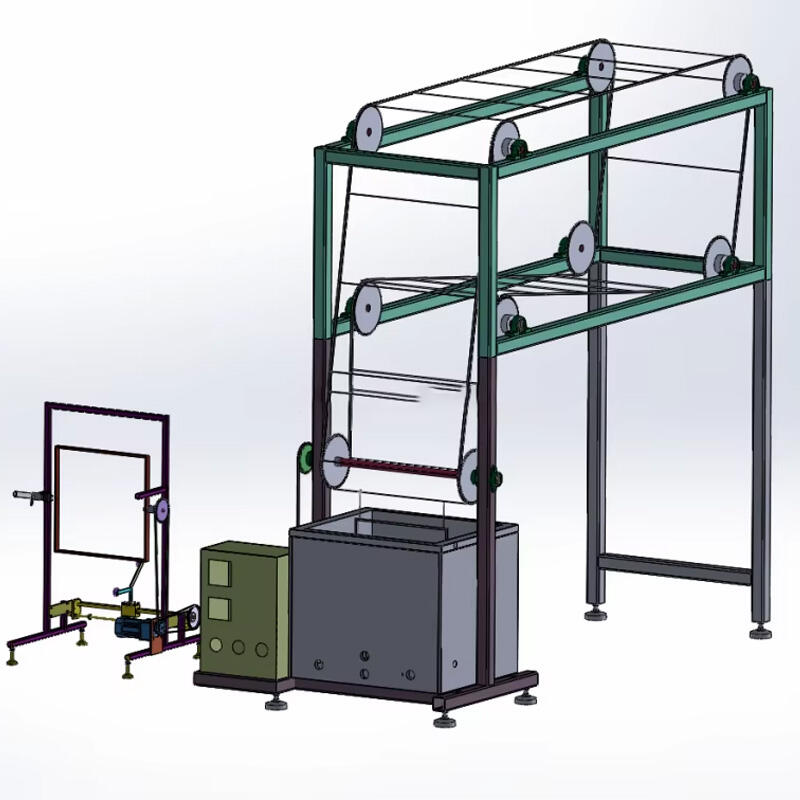

Dongguan Yide Machinery Co.,Ltd specializes candle machine manufacturing. most popular products wax melting tank, wax-filling machine wicking machines. have more manual candle machine semi-automatic candle machines stock, two fully automatic lines kept stock.

Providing manual candle machine warranty period as well lifelong maintenance program, expert inspection videos pictures will sent out clients prior shipment. After-sales problems will resolved within hour solution will offered within 24 hours. clients impressed skilled team foreign trade as well friendly service. We have skilled RD department will turn ideas into functioning machine. our production team responsible each steps your production until get product.

Three QC employees 8 steps quality manual candle machine ensure machine 100% reaching standards safety operation.We group comprised five professionals who give customised solution just 48 hours. Perfect equipment candle making business. We build machine accordance requirements.

equipment manual candle machine food grade stainless steel that resistant corrosion, anti-rust resistant high temperatures.normal motor replaced stepper motor servo motor increase accuracy efficiency. pump manufactured food grade stainless steel 316 instead iron plastic.There different sizes pumps, 20L 4L/6L/10L, suit different filling ranges. touch screen PLC makes easy set parameters, such as filling range, filling speed, temperature request more. Full range candle-related equipment choosed, not only semi automatic also fully automated types. machines have been updated make more adaptable, stable.