Candle Making Machine- A Playful Toy for Creating Candles

Do you like warm candlelight? Have you ever considered making candles at home but immediately felt distanced by the thought of how complex it must be? No worries, the candle making machine is here to keep you free during your candle-making journey. We decided to do a little digging into this remarkable tool that is sure to change the paradigm of candle making.

Advantages:

Advantages of Candle Making Machine Time Conservation: It works as a time-saving tool for you when making candles. It is especially beneficial when you intend to make candles in volume. More importantly, reliable quality in each candle they make. The candle-making machine also ensures that all candles made through it promotion uniformity in the making process they too will be easier on the eye and burn evenly! Finally, although the cost of purchasing a machine initially can be expensive compared to ready-made candles, it shows savings over time. If you plan to make a large amount of candles then the machine could end up saving you some cash.

Innovation:

The candle making machine is a big break-through in the old world of craft-making. It has managed to make a craft with centuries of history modern and accessible. Before this method was introduced, the process of creating a candle called for different ingredients to be mixed and melted together. Where a machine can create these through molds and hot wax, Its innovative design is attractive to new and seasoned candle makers.

When you are utilizing a candle making machine, the very first thing that needs to be ensured is the safety of users. The machine is build for the most part tamper-proof. Nonetheless, you may want to take some precautions when using it like making sure that your machine operates in a ventilated place since there is melter wax. In addition to the wax kit, these include temperature control which stops you from heating the material so much that it begins causing scalds or burns. Also, the wax is heated in a locked container, so you will avoid accidents that can happen with melting when using an ordinary stove.

It is easy to use The Candle Making Machine. You can use the following steps to do so: Select a type of candle mold, Melt some wax chips or blocks in cone-shaped heating chamber. This already melted wax can then be poured into the mold, left alone to cool and harden. Step 7: Once the candle is set, remove it from the mold and cut the wick as required. It preparation with various of molds, so that you can make candles according to the structure and size.

How to Use:

While the object is relatively straightforward to operate there's a learning curve involved. One that stands out is you must read the lengthy user manual properly in order to use it safely. Inside the manual, you have some really useful instructions on how to use your device and maintaining it along with cleaning tips too. You must employ ingredients specially designed for candle making machines and nothing but the approved ones.

If you have any issues using the device, there are different ways to contact your product manager to solve them and hotline dedicated for customer services. Ideally you will want to purchase your machine from reputable dealers and manufacturers that offer some type of warranty, technical support for problems that may occur.

Machine made candles are also man-handcrafted quality. The machine also provides candles in standard shape and size so that the final look seems polished. Thats why they advise you go to purchase a candle machine if want to make candles in the amount.

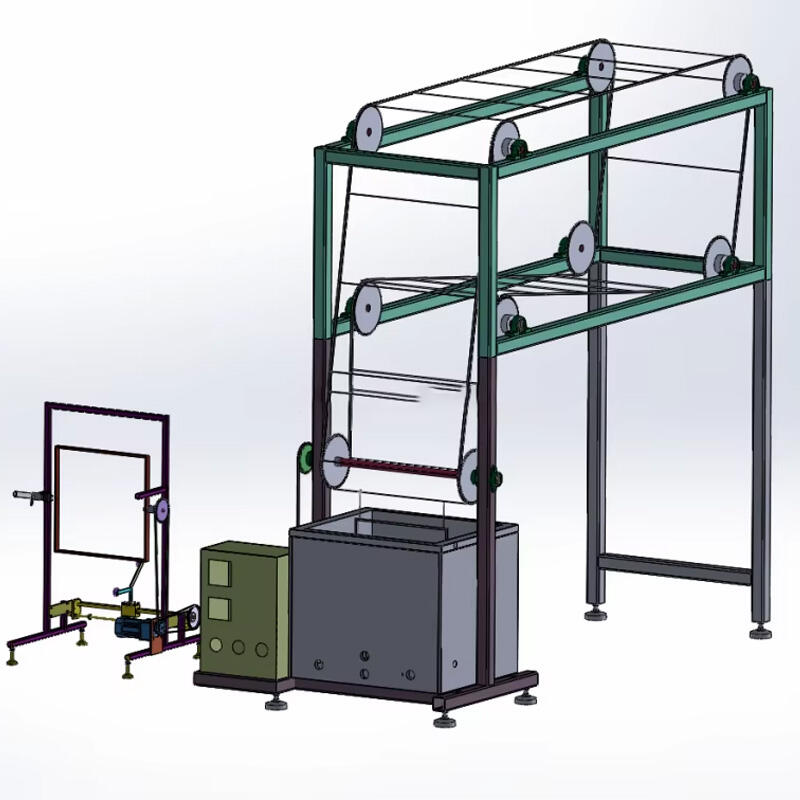

candle making machine Yide Machinery Co.,Ltd focused production candle machines. main product wax melting machine, filling machine, wick machine. manufacturing plant covers 2500 square meters. standard semi-automatic candle machine 100 sets, fully automatic line always keep two sets stock. believe sharing most efficient engineering solutions candle manufacturers around world.

equipment manufactured food grade stainless steel which anti-corrosion, anti-rust resistant high temperatures.motor normal model replaced an servo stepper motor greater accuracy efficiency. Additionally, pump constructed food grade stainless steel instead iron plastic.We offer different sizes of pumps, including 4L,6L 10L candle making machine and 20L meet different filling range. touch screen PLC allows easy adjustmentparameters. instance filling ranges, speed which filling done temperature requirement lot more. full range candle equipment that can selected, just semi automatic also fully automated type. machine updated detail, more adaptable more stability.

After-sales problems resolved less than hour. customers appreciate experienced team foreign trade professionals professional service. We have professional candle making machine department will turn ideas actual machine. Production responsible each step production, until receive products.

Three QC employees Eight stages candle making machine control, safety tests ensure machine compliance requirements safety usage.We a team comprising five professionals provide with custom solution 48 hours. perfect machine your candle making business. can make machine according your specifications, just meet requirements.