Knowledge of candle making is as old a tradition in our civilization. It began as a craft, like all crafts; now it has become an industry where art meets technology. One of the many things which have been developed in this sector includes cutting-edge candle filling machines that are a fundamental part of how candles can now be developed and produced. All combined together, this new technology allows for faster and more precise manufacture of candles at scale whilst resetting the bar on what should be considered efficient production in modern candle workshops giving us a whole green-friendly solution.

Well making perfect candles is integral to any sound and successful candle-making business. These innovative, state of the art candle filling machines have changed the way candles are made by providing accurate dispensing capabilities that ensure each and every oum of even body fill for all your wax products. The new technology, which employs a computerized pump and sensors, makes an exact calculation of the quantity of wax needed for each candle without any waste or leaking. Not just does that improve the overall quality and standardization of construction items, yet it also eliminates 60 percent less material, therefore using less money to produce new ways for production.

Candle Filling Equipment-Features to Look for When ProcuringThe two specific features outlined earlier on are not the sole considerations one must have when procuring candle filling equipment but they can make a huge difference. First and foremost, an essential criteria on the machines is that they had to be flexible enough able adapt a number of waxes (including soyand beeswax), along with multiple container measurements. They have to work on scalability, doing more and faster and being able switch between thousand of this quickly which high throughput calls for it. These advantages merge seamlessly with an easy-to-use interface and a maintenance-free operation to provide you the smoothest workflow. In addition to machines that utilize modes of automatically controlling the quality and making wax flow more like due to adjust resulting from temperature; such features enable a simple steps for candle production.

The candle fillers can change the future of any enterprise and take them to an entirely new dimension. New market trends are trying to make the production line more efficient and faster than ever. In addition, because the filling stage filled with faster cycle times and less manual labour also that supports your growing business as it allows you to launch a new product line or spend time working on more strategic things such innovation/marketing. Automated filling also produces an advanced level of uniformity, which translates to a recognizable brand identity for customers who will not accept anything less than perfection with every single candle in the range.

Every big retailer started just like you: with a little workshop, even if that was the first corner of another store selling candles and wax. Since the systems are modular and space saving up to 2/3 smaller than tradition fillers, a workshop station can be installed quickly with little downtime; these additions also cut back on human activity since computers reduce both manpower needed to operate equipment as well as risk of injury. Informed Consumer, Lean Expertise- The advanced journey of production can be achieved through air filter workshop armed with the basics and operation knowledge to strategize ways for peak operational efficiency but productive work space using lean manufacturing prominence alongside incorporating machinery solutions that will provide fundamentals.

Similarly, jungle bothy is great for the planet as a green candle making solution to steer clear of leaving negative footprints on our Earth.

One decade into the 21st century saw a rise in eco-thinking among the mainstream, as sustainability became more of an integral plank for consumers and business. But the candle sector has made a great deal of progress in wax filling solutions for sustainability as proven by these manufacturing sectors footprints. It has energy efficient features designed into the home, recyclable materials used in its construction and natural wax consumer options. Advanced technologies offer closed-loop systems that virtually eliminate waste, by preventing wax from leaking in transfer and spills. By employing these candle making environmentally sound and green practices, it not only proves how we care for our planet but would also reel in those customers concerned about the area which is a win-win situation.

The candle filling machine marks a significant milestone in the process of making candles This smart machines not only help in effectiveness of operations, productivity but also support the environment friendly practices which opens endless possibilities for candle makers to get more creative while moving to future sustainable life style into eco-friendly chilling method of making candles.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images will emailed clients prior shipment. After-sales problems will resolved within hour solution will offered candle filling equipment hours. clients impressed skilled team foreign trade as well considerate service. We have experienced RD department will your ideas a working machine. And production team responsible each stage production point you receive product.

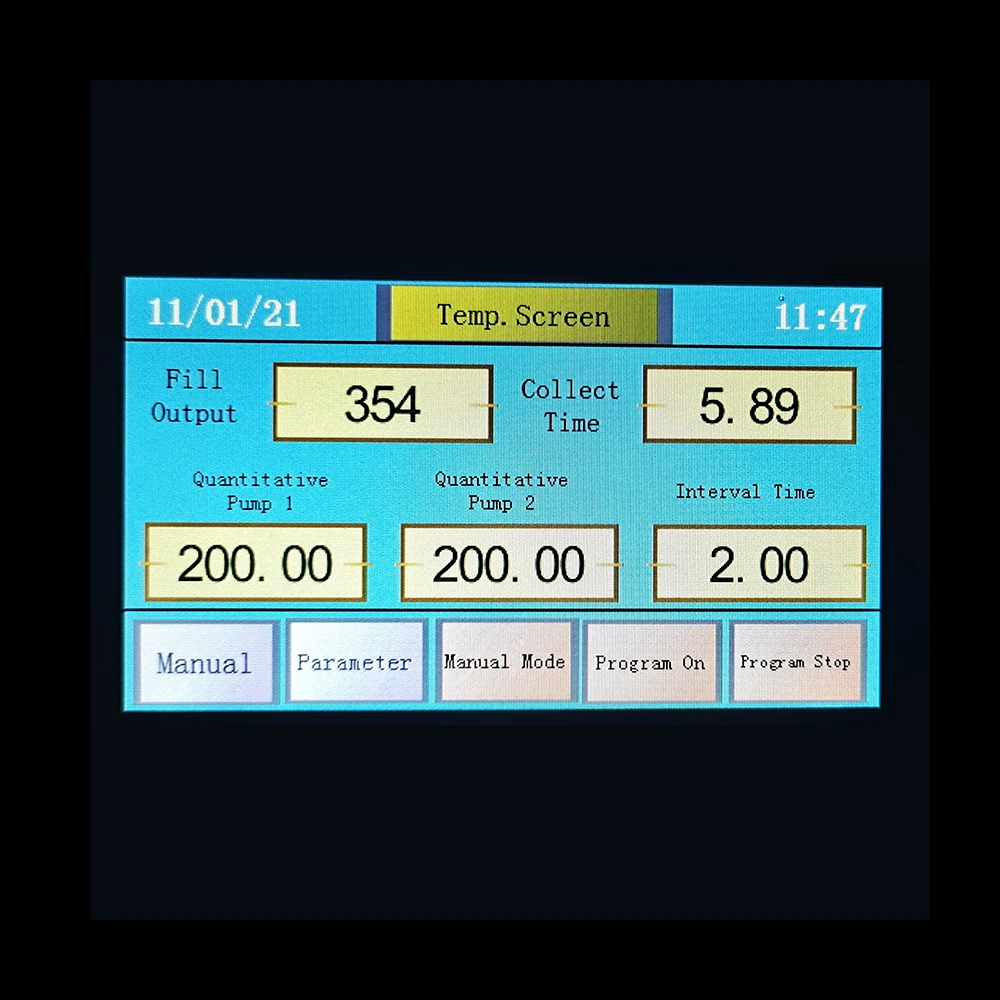

equipment constructed stainless steel food grade that corrosion-resistant anti-rust. It stands temperatures to certain point.order ensure efficacy precision ensure accuracy efficiency, stepper motor as well servo motor substituted normal motors. pump constructed stainless steel food grade type instead plastic iron.offer different sizes pumps 4L 6L candle filling equipment 20L meet different filling range. touch screen PLC design allows you easily adjust parameters. example, filling ranges, speed which filling done as well temperature requirements more. There's wide assortment candle-related equipment available, not semi-automatic model as well fully-automatic one. machines upgraded terms detail, allowing more flexible stable.

Three QC employees, eight stages quality control, safety tests ensure machine compliance guidelines safety use.We a group five professionals who offer you custom solution just 48 hours. ideal equipment candle manufacturing business. We candle filling equipment build machine meet requirements.

Dongguan Yide Machinery candle filling equipmentLtd focused production candle machines. main product wax melting tank, wax filling machine wick machine. factory cover area approximately 2,500 square metres, standard semi-automatic candle machine over 100 sets. fully automated line always two sets stock. We have commitment sharing most efficient engineering solutions candle manufacturers around world.